Sound Level MeterS Calibration

Fast turnaround means little downtime

Our calibration laboratory can perform calibrations on sound level metres as well as calibrators of both Class I and Class II variations.

For more information on our sound calibration services,

give us a call or fill out the calibration form to the right, and we'll get

back to you as soon as possible. We can calibrate sound metres of both types 1

and 2, as well as personal noise dosimeters and type 1/type 2 acoustic

calibrators.

We offer calibration on the following anemometers and

wind speed meters,

Sound Calibrators,

Sound Level Calibrator,

Class 1 Acoustic Calibrator,

Class 2 Acoustic Calibrator,

Sound Meter Acoustic Calibrator,

Sound Meters,

Sound Meter,

Sound Level Meter,

Noise Meter,

Decibel Meter,

Audiometer,

About Sound Level Meters

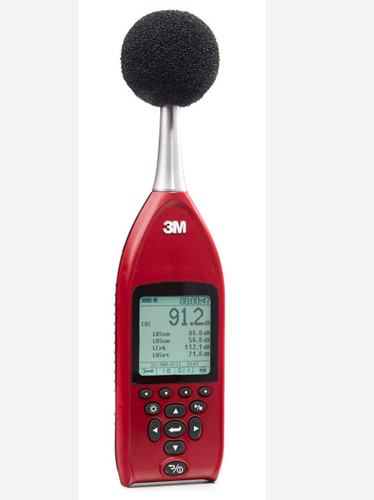

Sound Level Meters (or Sound Meters) are the instruments

that measure sound pressure levels. Sound Pressure Level (or Sound Level) is a

logarithmic measure of the effective sound pressure of a sound relative to a

reference value. It is measured in decibels (dB) above a standard reference

level. The standard reference sound pressure in air is 20 ?Pa, which is usually

considered the threshold of human hearing (at 1 kHz). Sound Pressure Level (Lp)

is calculated according to the following formula:

where:

pref is the reference sound pressure, and

prms is the rms sound pressure being measured.

Sound level meters are commonly used for measuring

several kinds of noise, especially for industrial, environmental and aircraft

applications.

According to IEC 61672-1 “Electroacoustics – Sound level

meters, Part1: Specifications”, there are three kinds of sound level meters:

The conventional sound level meter that measures

exponential time-weighted sound level.

The integrating-averaging sound level meter that measures

time-average sound level.

The integrating sound level meter that measures sound

exposure level.

A sound level meter can perform any one, or all, of the

above three kinds of measurements. Frequency weighting A is mandatory for all

sound meters since its use is required in all countries in order to protect

workers against noise-induced deafness.

A frequency weighting A is also mandatory in all civil aircraft noise

measurements.

Frequency weighting C is only mandatory for sound level

meters conforming to class 1 tolerance limits (classes are explained below).

The Zero frequency weighting (Z-weighting) is optional.

Sound level meters are commonly used to measure sounds

generally in the range of human hearing. Their main components are a

microphone, a signal processor and a display device. A sound level meter may be

a self-contained hand-held instrument with an attached microphone and a

built-in display device or it may comprise of separate components in one or

more enclosures and may be capable of displaying a variety of acoustical signal

levels. Depending on their construction, sound level meters are also classified

into three groups as follows:

Group X sound level meters: self-contained instruments

which operate, in normal mode, with internal battery power, requiring no

external connections to other apparatus.

Group Y sound level meters: self-contained instruments

which require connection to a public supply of electric power for the normal

mode of operation, requiring no external connections to other apparatus.

Group Z sound level meters: instruments which require two

or more items of equipment, which are essential constituent parts of the sound

level meter, to be connected together by some means for the normal mode

operation. The separate items may be operated from internal batteries or from a

public power supply of electric power.

Depending on their accuracy, sound level meters are

divided into two performance categories, class 1 and class 2. Sound level

meters of both classes have the same functionality but they differ mainly in

the tolerance limits. Class 1 instruments have a wider frequency range and a

tighter tolerance than class 2 sound level meters which are lower cost

instruments. In the following table the tolerance limits (in dB) of each class

are presented in some indicative frequencies, as stated in IEC 61672-1:

Sound Level Meter Calibration

Having analyzed what a sound level meter is and how it

works, we can now see, how it is calibrated

First of all, according to IEC 61672-1, the reference

environmental conditions of a laboratory performing sound meter calibrations

should be:

Temperature: 20 to 26 oC

Static Pressure: 80 to 105 kPa

Relative Humidity: 25 to 70%

The environmental conditions of the laboratory shall be

measured and recorded during the calibration.

Prior to any measurements, the sound level meter and all

accessories shall be visually inspected, paying particular attention to damage

to, or accumulation of foreign materials on the protection grid or diaphragm of

the microphone. Also, before conducting any test, the voltage delivered by the

power supply for the sound level meter shall be checked to ensure that it is

within the specified operating limits.

In order to calibrate sound level meters, a sound

calibrator must be used. According to IEC 61672-1, at least one model of sound

calibrator shall be stated in the sound level meter’s instruction manual for

checking and maintaining the correct indication on its display. For class 1

sound level meters, a sound calibrator conforming to class 1 specifications of

IEC 60942 is required. For class 2 instruments, the sound calibrator shall

conform to either class 1 or class 2 specifications of IEC 60942.

The sound calibrator usually provides a reference sound

pressure level of 94 dB or/and 114 dB at the frequency of 1 kHz. The sound

calibrator must have a traceable and documented calibration certificate from a

higher level laboratory (often from a national metrology institute).

When calibrating a sound level meter, most of the

laboratories perform the calibration frequency check. In order to conduct this

test, the operator must connect the sound meter to the corresponding calibrated

sound calibrator and check that the instrument is within the tolerance limits.

If necessary, the sound level meter can be adjusted to indicate the required

sound pressure level.

Sound Level Meters – Periodic Tests

Besides the aforementioned test, there are some more

tests that can be performed (depending on the type and the construction of the

sound level meter) which are described in IEC 61672-3 “Sound level meters –

Periodic Tests”:

Self-generated noise with microphone replaced by an

electrical input signal device

With the microphone replaced by an electrical input

signal device and terminated in the manner specified in the instruction manual

for measurements of the level of the corresponding self-generated noise, the

indicated level of the time-averaged or time-weighted self-generated noise

would be recorded for all frequency weightings available in the sound level

meter.

Acoustical signal test of a frequency weighting

The sound level meter shall be set for frequency

weighting C, if available, otherwise, it would be set for frequency weighting

A. In order to perform this test, a calibrated multi-frequency sound calibrator

(class 1) is required. The test is performed in three frequencies, 125 Hz, 1

kHz and either 4 kHz or 8 kHz (depending on the free-field adjustment data that

are provided, or at the discretion of the calibration laboratory).

Electrical Signal tests of frequency weightings

With this test, the frequency weightings are determined

relative to the response at 1 kHz, by using steady sinusoidal electrical

signals. On the reference level range and for each frequency weighting to be

tested, the level of a 1 kHz input signal shall be adjusted to display an

indication that is 45 dB less than the upper limit stated in the instruction

manual for the linear operating range at 1 kHz on the reference level range.

The test must be performed, for class 1 instruments, at the 10 frequencies at nominal

octave intervals from 31,5 Hz to 16 kHz and for class 2 sound level meters, at

the 8 frequencies at nominal octave intervals from 63 Hz to 8 kHz.

Frequency and time weightings at 1 kHz

The test is performed by applying a steady sinusoidal

electrical signal of 1 kHz with amplitude set to indicate 94 dB at frequency

weighting A. Then the performance of C-weighting, Z-weighting and FLAT response

are checked, with the sound level meter set to display F time-weighted sound

level, S time-weighted sound level and time average sound level (depending on

the functions available).

Level linearity on the reference level range

This test is performed by using steady sinusoidal

electrical signals of 8 kHz with the instrument set to frequency weighting A

and time weighting S. The amplitude of the signal, initially set to give an

indication at the reference level of 94 dB in each case, is increased in 5 dB

steps up to within 5 dB of the upper limit of the linear operating range. The

signal is then increased in 1 dB steps until, but not including, the first

indication of overload. The tests are then continued, again starting from the 94

dB level with the signal decreasing in 5 dB steps down to within 5 dB of the

specified lower limit. The signal is then decreased in 1 dB steps down to, but

not including the first indication of under-range or the lower limit of the

linear operating range.

Level linearity including the level range control

This test is performed by using a steady sinusoidal

electrical signal of 1 kHz with the sound level meter set to frequency

weighting A. The signal is adjusted to display a reference level of i.e. 94 dB

at the reference range of the instrument. The signal is kept constant while the

instrument changes ranges and the readings at each range are checked.

Toneburst response

The response of the sound level meter too short duration

signals shall be tested on the reference level range with 4 kHz tone bursts

that start and stop at zero crossings and are extracted from steady 4 kHz

sinusoidal input signals. The sound level meter shall be set for

frequency-weighting A.

Peak C sound level

Indications of peak C sound level shall be tested on the

reference level range. The test signals are a single complete cycle of an 8 kHz

sinusoid starting and stopping at zero crossings, and positive and negative

half cycles of a 500 Hz sinusoid that also start and stop at zero crossings.

Overload indication

This test of overload indication is only to be performed

for sound level meters capable of displaying time-average sound level. Overload

indication shall be tested on the reference level range with the sound level

meter set to display A-weighted time-average sound level. Positive and negative

one-half cycle sinusoidal electrical signals at a frequency of 4 kHz shall be

used. The one-half cycle signals shall be extracted from steady signals of the

same signal level and shall begin and end at zero crossings.

Of course, not all of the above tests are applicable to

all sound level meters. Only the indication at the calibration check frequency

is mandatory. The rest of the tests depend on the meter’s capabilities.

The calibration laboratory must provide in the

calibration certificate the uncertainty of measurement.

Calculation of the measurement uncertainty of sound level

meters calibration contains at least the following components:

The measurement uncertainty from the calibration

certificate of the standard instruments (i.e. sound level calibrator).

The uncertainty resulting from any environmental effects.

The repeatability of measurements.

Uncertainty due to the limited resolution of the sound

level meter under test.

According to IEC 61672-3, the actual expanded u