Flow measurement calibration

Fluid flow measurements in oil and gas production operations are used as the basis for revenue payment, determining well allocations, and controlling the process for certain systems. There are many types of instruments for measuring liquid and/or gas flow. The accuracy of flow measurement will vary from instrument to instrument and the desired accuracy will vary from application to application.

Measuring flow is one of the most important aspects of process control. It is one of the most frequently measured process variables. Flow tends to be the most difficult variable to measure. No single flow meter can cover all flow measurement applications.

The physical properties of fluids are important factor in flow metering accuracy. The major factors affecting the flow of fluids through pipes are:

The velocity of the fluid

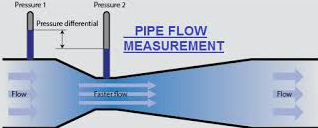

The velocity of a flowing fluid is its speed in the direction of flow. Fluid velocity depends on the head pressure that is forcing the fluid through the pipe. Greater the head pressures, faster the fluid flow rate.

Pipe size

Pipe size also affects the flow rate. Larger the pipe the greater the potential flow rate.

Friction due to contact with the pipe

Pipe friction reduces the flow rate through the pipe. Because of the friction due to the fluid in contact with the pipe, flow rate of the fluid is slower near walls of the pipe than at then the centre.

The viscosity of the fluid

The viscosity of a fluid refers to its physical resistance to flow. Higher the viscosity the fluid, the slower fluid flow.

The specific gravity of the fluid

Specific gravity of liquid is the density of the liquid/density of water. The specific gravity of gas is the density of the gas / the density of air. At any given operating condition, higher the fluid's specific gravity, lower the fluid's flow rate.

Fluid Condition

The condition of the fluid (clean or dirty) also limitations in flow measurement. Some measuring devices become blocked/plugged or eroded if dirty fluids are used.

Velocity Profiles

Velocity profiles have major effect on the accuracy and performance of most flow meters. The shape of the velocity profile inside a pipe depends on:

•The momentum or internal forces of the fluid, that moves the fluid through the pipe

•The viscous forces of the fluid, that tend to slow the fluid as passes near the pipe walls.

There are three types of flow profile.

•Laminar or Streamlined

•Transition

•Turbulent

•Laminar or Streamlined

Laminar or streamlined flow is described as liquid flowing through a pipeline, divisible into layers moving parallel to each other.

Turbulent

Turbulent flow is the most common type of flow pattern found in pipes. Turbulent flow is the flow pattern which has a transverse velocity (swirls, eddy current).

Transitional

Transitional flow profile exists which is between the laminar and turbulent flow profiles. Its behaviour is difficult to predict and it may oscillate between the laminar and turbulent flow profiles.