Temperature Calibration and repair Services UAE

• Provides a range of temperature calibration services including psychrometer calibration, recorder calibration, chart temperature calibration, digital temperature calibration, humidity testing, system accuracy tests, temperature controllers, digital readout calibration, RTD probe calibration, thermocouple calibration, no readout and module calibration, NIST thermocouple calibration, base metal, noble metal, thermocouple sensor calibration, temperature probe calibration, thermometer calibration, temperature gauge calibration, temperature datalogger calibration, thermal anemometer calibration, temperature transmitter, temperature chart recorder, temperature meter, RTD probes, temperature indicator calibration, autoclave, oven, and digital thermocouple calibration.

• Industrial temperature sensors are often more challenging to calibrate than laboratory standards due to their shortness, wide temperature ranges, and potential need for onsite calibration.

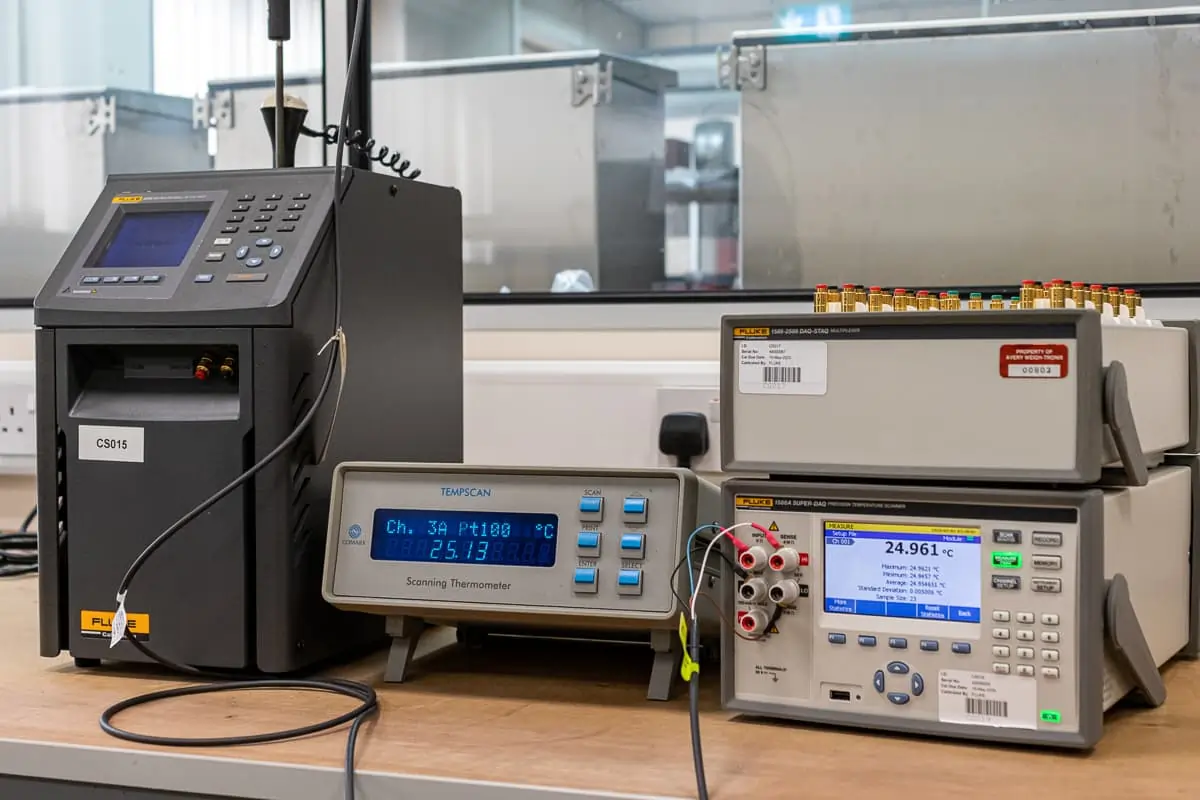

• we offers a variety of temperature sensor calibration solutions, including portable and larger bench equipment to generate temperatures ranging from -196°C to 1300°C.

• we offers reference thermometers and measuring systems in addition to portable heat sources.

• we provides fast temperature calibrators, portable liquid baths, and dry block calibrators, as well as measuring systems and automation software.

• we offers reference thermometers, measuring instruments, and automation software for controlling calibrators and instruments, stepping through a series of temperature calibration points automatically, and logging calibration results.

• we also provides on-site temperature calibration solutions, including sterilizer and autoclave validation (Temperature Validation Equipment), which requires an independent temperature reference source with a pocket to accommodate up to 12 temperature sensors.