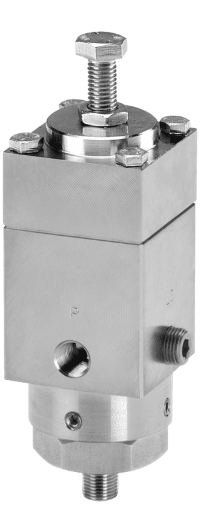

Pyropress Pneumatic Pressure Switch Testing and Repair

• A three-way block and bleed valve that operates by pressure acting on a piston.

• Functions as either a normally closed or normally open valve depending on the two ports through which instrument pressure is supplied.

• The output port, marked "OUT," remains the same for both modes of operation.

• When instrument supply pressure is connected to the "HI IN" port, the switch operates as a high switch.

• If sense pressure acting on the piston is at normal levels, the spool shifts and the center O-ring moves between the "HI IN" and "OUT" ports.

• To change the sense pressure value, alter the spring force, the size of the sense piston diameter, or both.