Refrigerant Recovery Units calibration

Understanding Refrigerant Recovery Station

Key Takeaways:

• Refrigerant recovery is a process to protect the environment, recover valuable refrigerants, and ensure efficient HVAC systems.

• Refrigerant recovery station components include cylinders, machines, and hoses for safe extraction of refrigerants.

• Technicians must follow safety protocols and regulations while using tools and techniques tailored to specific HVAC system needs.

Fundamentals of Refrigerant Recovery:

• Refrigerant recovery transfers a system’s refrigerant into a refillable cylinder for repairs or replacement of the air-conditioning system.

• Benefits include minimizing the release of synthetic refrigerants into the atmosphere, providing long-term cost savings, and enhancing the financial performance of industrial refrigeration system operators.

Tools and Equipment Used in Refrigerant Recovery:

• Valve core removal tools to access the refrigerant within the system.

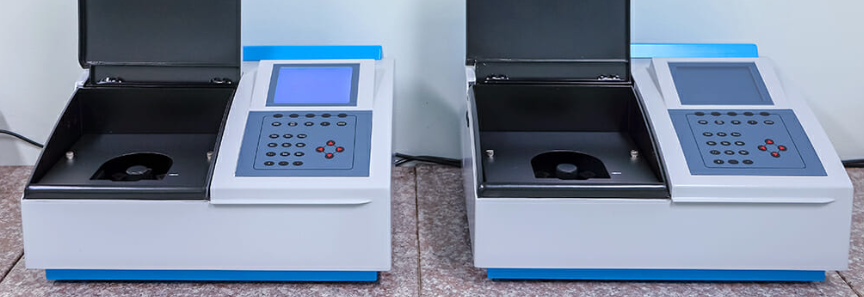

• A refrigerant recovery machine to transfer the liquid refrigerant into a cylinder for storage or recycling.

• The recovery machine also purifies and filters the refrigerant, ensuring its quality and compliance with international standards.

Anatomy of a Refrigerant Recovery Station:

• Components include a recovery cylinder, a recovery machine, a manifold, hoses, and valve core removal tools.

• Hoses connect different components, facilitating the flow of refrigerant during the recovery process.

The Recovery Process Unveiled:

• The recovery process consists of three main steps: preparing the recovery station, executing the recovery phase, and performing post-recovery procedures.

Setting Up a Recovery Station

• Connect hoses, valves, and cylinders.

• Close all valves, including those on the recovery cylinder, recovery machine, manifold, and hoses.

• Assemble the hoses according to the provided diagram.

• Connect the liquid port of a dual valve/port recovery cylinder to the liquid side of the plant.

Safety Measures

• Document the amount and type of refrigerant recovered to adhere to regulations.

• Ensure the recovery equipment, recovery cylinder, and hoses are compatible with the specific refrigerant being recovered.

• Consult with the equipment supplier for further guidance.

Maintenance of Safety

• Accurately calibrate the equipment.

• Check for any possible leaks.

• Adhere to safety protocols.

• Have a backup power source.

• Correctly label and store recovered refrigerant.

Recovery Phase

• Technicians extract refrigerant from the HVAC system using methods such as direct recovery or push/pull.

• The push/pull method connects the liquid port of a dual valve/port recovery cylinder directly to the liquid side of the plant.

• An inline sight glass allows technicians to observe when liquid flow has ceased.

Post-Recovery Procedures

• Purge the recovery cylinder using a scale.

• Cool the recovery cylinder to reduce pressure within the cylinder.

• Use an inline filter for improved sustainability, cost savings, enhanced refrigeration system performance, and alignment with environmental regulations.

Optimizing Recovery Efficiency

• Use appropriate tools like the Inficon Vortex Dual refrigerant recovery machine and compliance management software.

• Temperature and pressure optimization are important factors in enhancing recovery efficiency.