HAZARDOUS AREA CLASSIFICATION

Hazardous areas are classified into zones according to the degree of risk.

ZONE 0 Where an explosive atmosphere is continuously present for long periods.

ZONE 1 Where an explosive atmosphere is likely to occur in normal operation.

ZONE 2 Where an explosive atmosphere is not likely to occur in normal operation and if it occurs it is only present for a short period.

Typical example of a hazardous zone side plan for an offshore installation is shown in Figure 1.

Selection of apparatus according to Zones

Electrical installations in hazardous areas should be kept a minimum. However, in areas where electrical equipment has to be installed, a code of practice has been developed to enable specific selection of various electrical equipment suited to the zones and the types of protection allowed, see the table in

There are various methods used to prevent electrical apparatus from igniting the surrounding atmosphere when energised.

1) Flameproof Enclosures, type Ex ‘d’

Equipment that could ignite an explosive atmosphere is housed within a substantial enclosure. This is capable of containing an internal explosion without transmitting that explosion to the surrounding explosive atmosphere.

2) Increased Safety, type Ex ‘e’

An increased measure are taken to prevent the generation of arcs, sparks and excessively hot areas in equipment thus preventing the risk of explosion inside or outside of the enclosure.

3) Intrinsic Safety, type Ex 'i'

Power is limited to this equipment in such a way that a spark or a hot surface would not he hat enough to ignite the explosive atmosphere.

4) Pressurised, type Ex 'p'

Here the concept used is to house the equipment in an enclosure, which is pressurised or purged by inert gas, thus preventing an explosive atmosphere from reaching the equipment.

5) Oil Immersion, type Ex ‘O’

All equipment is totally immersed in oil, thus preventing an explosive atmosphere from reaching the equipment.

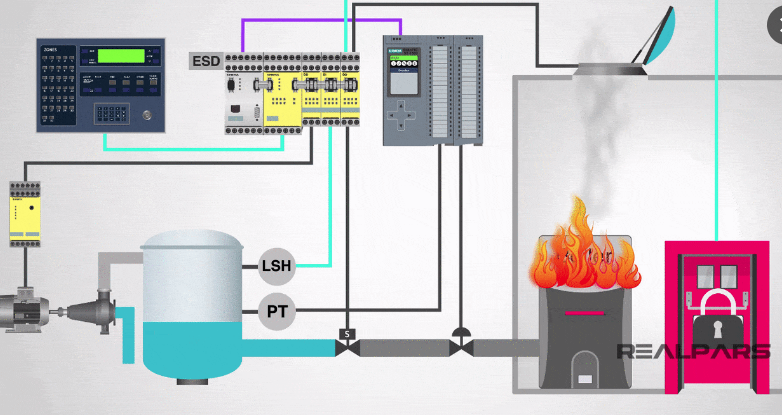

Figure 1. Typical Hazardous Area Zoning

6) Powder filled, type Ex 'q'

All equipment is totally immersed in powder, thus preventing an explosive atmosphere from reaching the equipment.

7) Non-sparking and Restricted Breathing, type Ex 'n' or ‘N’

This gives a level of protection by housing electrical equipment in substantial enclosures that inhibit mechanical damage and give some degree of ingress protection.

8) Special Protection, type Ex 'S'

This applies to items of equipment not entirety covered by any of the foregoing concepts but one that can clearly be demonstrated to be explosion-proof.

9) Moulded/Encapsulated, type Ex 'm'

The apparatus is totally encapsulated by a non-porous compound. Electrical connection is by flying leads.

Apparatus Selection within Zones

Zone Suitable Apparatus

Zone 0 Ex ‘ia’, some Ex ‘s’

Zone 1 All types except Ex ‘n’

Zone 2 All types

Hazardous materials vary in their ease of ignition and this is recognised by grouping either them, or the apparatus, into order of severity. This is done in two separate ways:

1. By their capability of being ignited by sparks or flames (gas group)

2. By their capability of being ignited by not surfaces (gas temperature class)

Spark or Transmitted Flame Ignition

The possibility of spark ignition exists in electrical apparatus and may occur during either its normal operation or under fault condition.

All electrical apparatus is grouped according to the ignition energy produced, in terms of the gas-air mixture that it will not ignite. There are four groups in Europe:

Gas Groups

Gases are grouped together according to their degree of hazard. This is based on the amount of energy required to light the gas/air mixture.

Gas Group Representative Gas

I : (Mining)

IIA : (Surface)

IIB : (Surface

IIC : (Surface) Methane

Propane

Ethylene

Hydrogen

Hot Surface Ignition