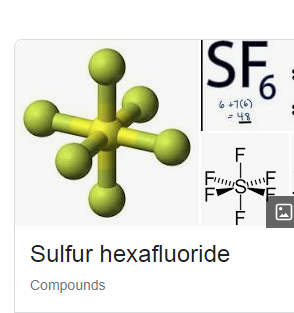

SF6 Gas Handling

• SF6 gas is a potent greenhouse gas used in electric power systems and industries.

• Proper gas handling practices are crucial to minimize emissions.

• Pro tips include relieving pressure before disconnecting, following proper start-up procedures, preparing equipment, recovering gas on failed breaker, checking filters, testing SF6 cylinders, and using nitrogen to rinse the recovery system.

• If a breaker fails, a gas analysis should be performed and a small amount of SF6 gas recovered.

• Nitrogen can be used to rinse out internal components if a recovery system becomes contaminated with sulfur dioxide.